What to Look for in a Blown Film Die Blown Film Series Part III DavisStandard

Blown Film Calculations April 14, 2015 Amy Laird . Area of the die, bubble Flow rate at die, frost line Line speed, strain rate Changing the strain rate Draw down ratio Questions? Agenda . 3. • Blow-Up Ratio = D bubble /D die = 2.5 • Bubble diameter = BUR * D die = 62.5 cm

Blow up ratio Big Chemical Encyclopedia

Low blow-up ratios, low film thicknesses, high melt temperatures and high blower outputs have a particularly positive effect on the increase in mass throughput, so that the throughput can be increased by up to 62% in the experiments. However, the developed system leads to an ∼3% increased film thickness variation.

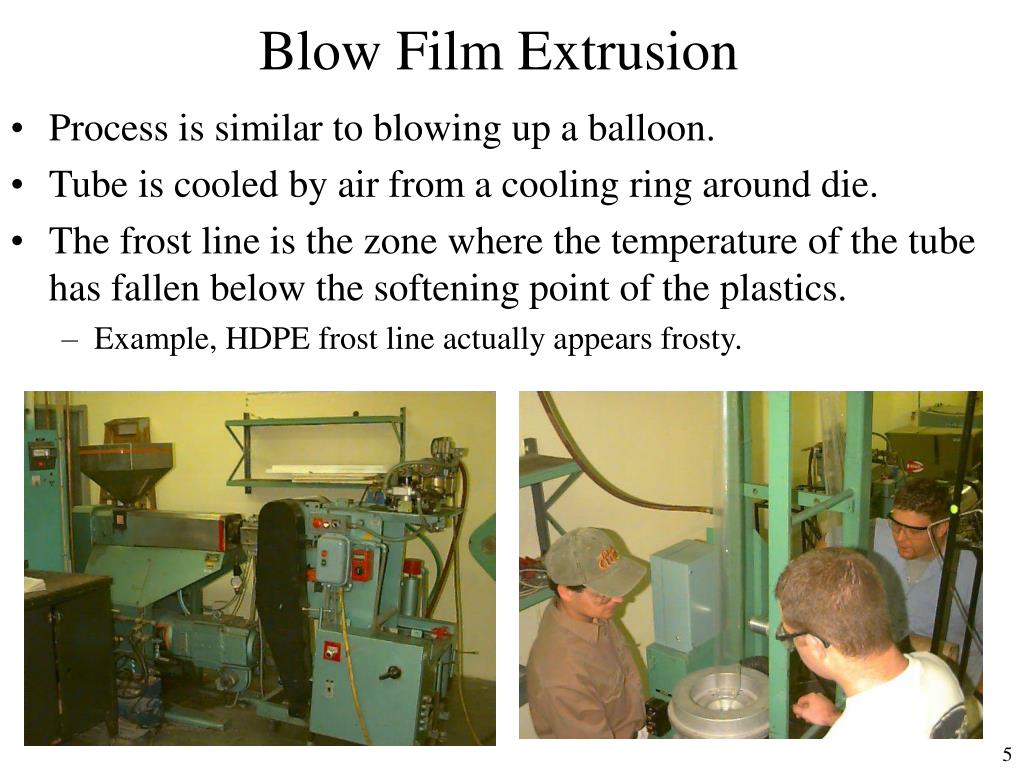

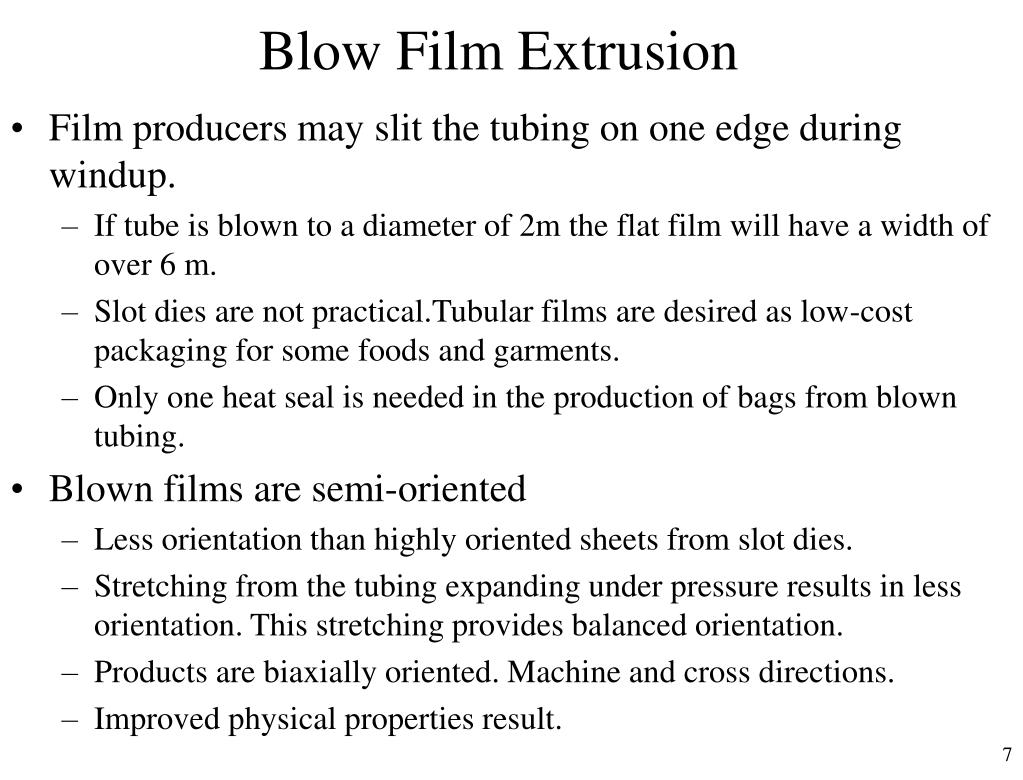

PPT MFGT 142 Polymer Processing Blow Molding PowerPoint Presentation ID4691777

How the blow-up ratio and resin characteristics affected the final film morphology and engineering properties were studied. The crystalline morphology and orientation during the blown film process of the low-density polyethylene film were investigated using small-angle X-ray scattering, transmission electron microscopy and scanning electron.

Polyethylene (PE)

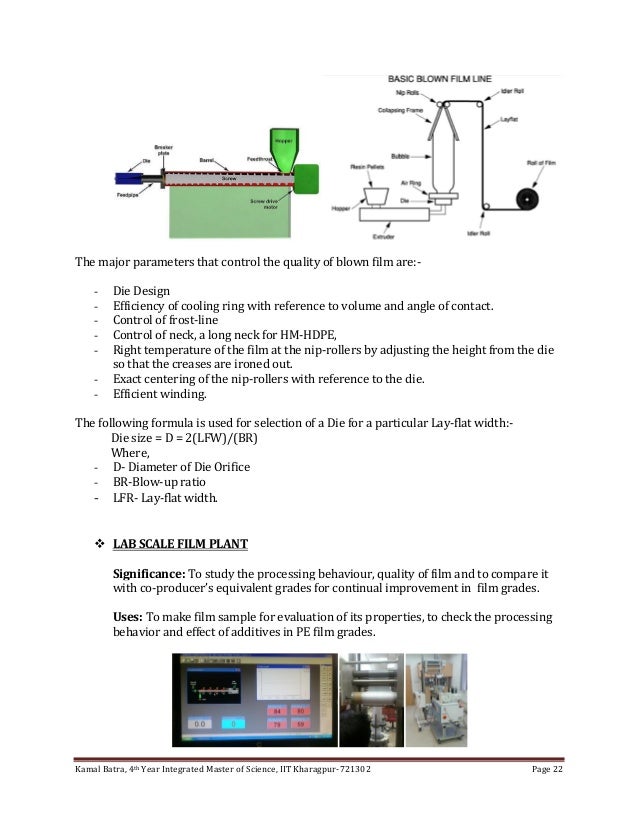

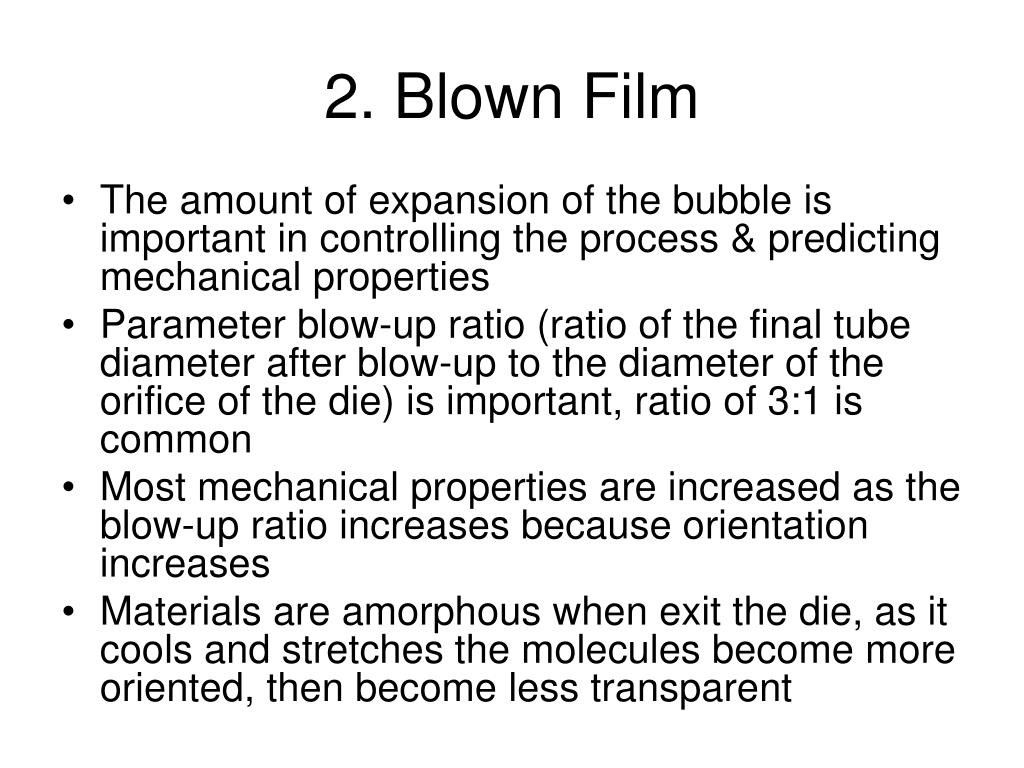

The Blow-Up ratio (BUR), is the ratio of the bubble's diameter at the FLH to that at the die exit. The FLH is the height at which, the bubble's radius and the film thickness become fixed. Moreover, it corresponds to the optimum cooling and desired film properties.

PPT MFGT 142 Polymer Processing Blow Molding PowerPoint Presentation ID4691777

312 Blown film The bubble diameter is normally always greater than the die diameter. This bubble diameter divided by the die orifice diameter is called the blow-up ratio (BUR) (Fig. 2.20). The bubble diameter must not be con fused with the width of the flattened double layer of film between the nip rolls.

Blown Film Plascon Group

For HMW-HDPE the typical blow up ratios (BUR) are 3.5-4.5:1. BURs may be varied depending on the film properties desired for the product being produced. The larger the BUR, the higher the machine direction tear. The lower the BUR, the higher the transverse direction tear value. The neck height (long stalk) for most resins is six to

Picture of the blown film process. Download Scientific Diagram

Elements of blown film • Film thicness: 6 - 250 microns • Layflat width: 600 - 4000mm • Die diameter: 100 - 600mm • Die gap: 0.8 - 2.8 mm • Bubble diameter • BUR (blow up ratio): 2 - 4.5 • DDR (draw down ratio) = gap width/thickness x BuR • MD (machine direction) • TD (transverse direction) • L/D ratio of screw: 24.

PPT ExtrusionBased Processes PowerPoint Presentation, free download ID6821315

The effect of temperature, extrusion rate, stretching (TUR) and blow-up (BUR) ratios were evaluated to determine the optimum processing conditions for blown films based on the bubble stability and to determine their final tensile properties. As expected, the processing temperature was the most critical parameter on the film stability.

Blown Film Extrusion Process Blown Film Extrusion Process In Hindi Blown Film Extrusion

The final film dimensions are determined by a number of process variables such as the blow up ratio (BUR), which is a ratio of the bubble radius at the freeze line to the radius of the die, and the machine direction draw down ratio (MDD), which is the ratio of velocity at the nip rollers to the velocity of the polymer melt exiting the die.

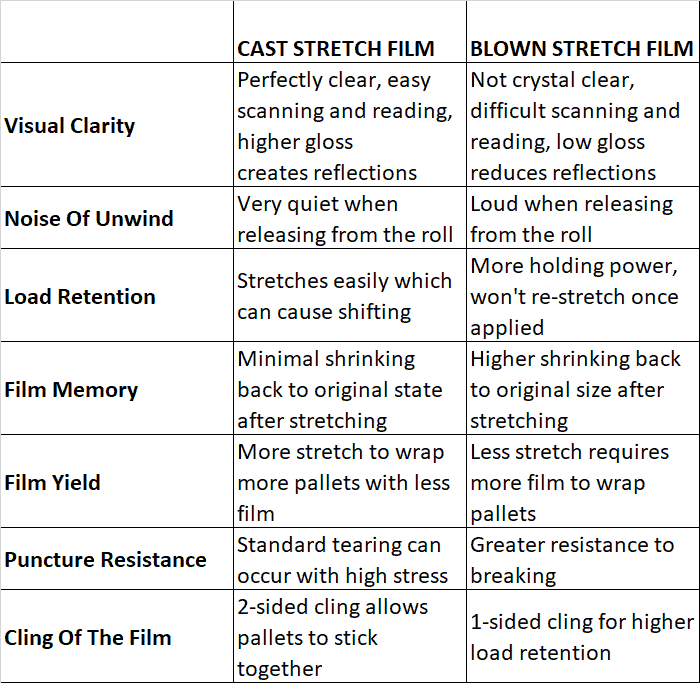

Cast vs Blown Stretch Wrap Packaging 360

The results obtained by the method of linear stability analysis indicate that the blown film process becomes unstable if the blow-up ratio (BUR) or the film thickness reduction is larger than a certain critical value. In addition, existence of an optimum freeze-line-height is predicted at which the region of stable operation is largest in terms.

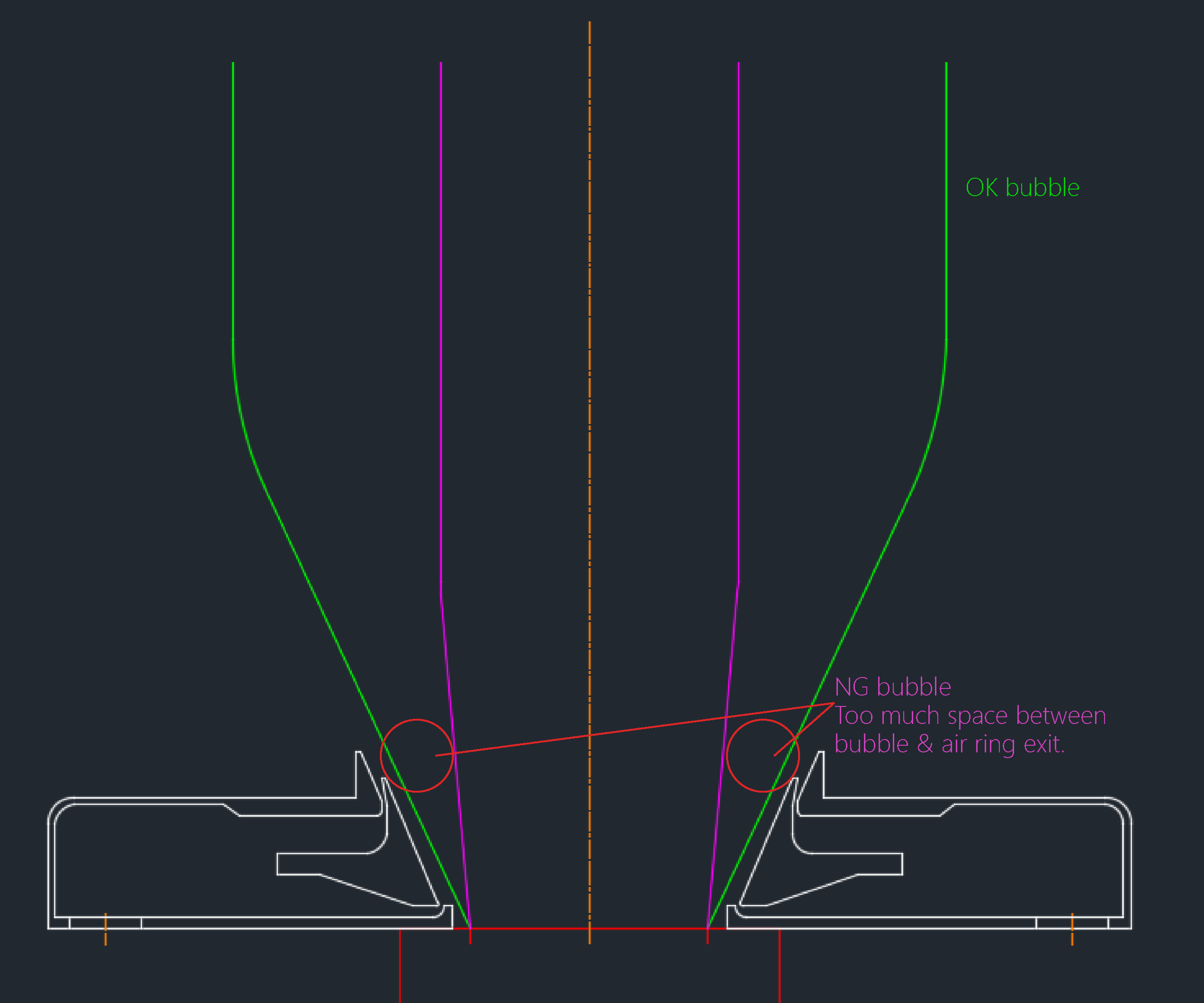

C.Y. Frequently Asked Questions Blown film air ring, die and blown film machine parts

The Film Extrusion Process Operation of a Blown Film Line9 Materials Conditioning/Handling 9. Blow-up Ratio 32 Cooling 32 Process Variables Controlling Property Improvement 33 33 33 33 33 33. is crystallinity up to 85%. Low density PE resins generally have crystallinity from 35

What is blown film extrusion process? How do you calculate blow up ratio? What is DDR and DBR

extruding polyethylene into blown film. For example, blow-up ratio (BUR) used alone as a film-making parameter is meaning-less. BUR must be related to draw-down ratio and die gap. In Figure 3, all three of these parameters are used to illustrate a theory of melt orientation, an important factor in extruding the high quality film required by.

Blown Film and How it works?

There are four key factors to consider in order to successfully produce a multilayer film: 1) polymer selection, 2) process equipment design, 3) layer arrangement, and 4) process conditions. Problems in blown film coextrusion arise when insufficient consideration is given to one or more of these factors. Five common problems associated with.

Blow up ratio Big Chemical Encyclopedia

The blow-up ratio (BUR) is defined as the ratio of the final bubble diameter to the die .. Blown film can be produced in gauges as high as 0.5 mm and as thin as 0.005 mm. The blown film.

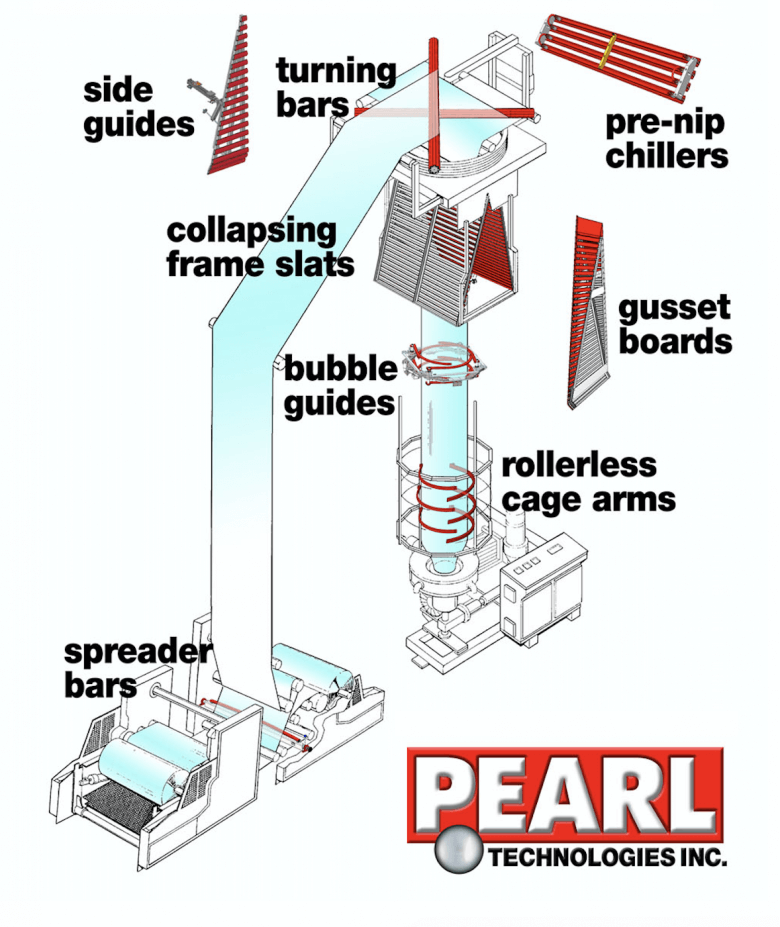

Understanding Blown Film Extrusion The Future of Extrusion Pearl Tech Inc.

Keywords Polyethylene, blow-up ratio, LLDPE, blown film, morphology Introduction Polyethylene (PE) possesses good properties for packaging film applications, such as flexibility, strength, toughness, lightness, stability, moisture, and chemical resistance. Although the PE blown film process is widely used for film production, how PE crystalline.

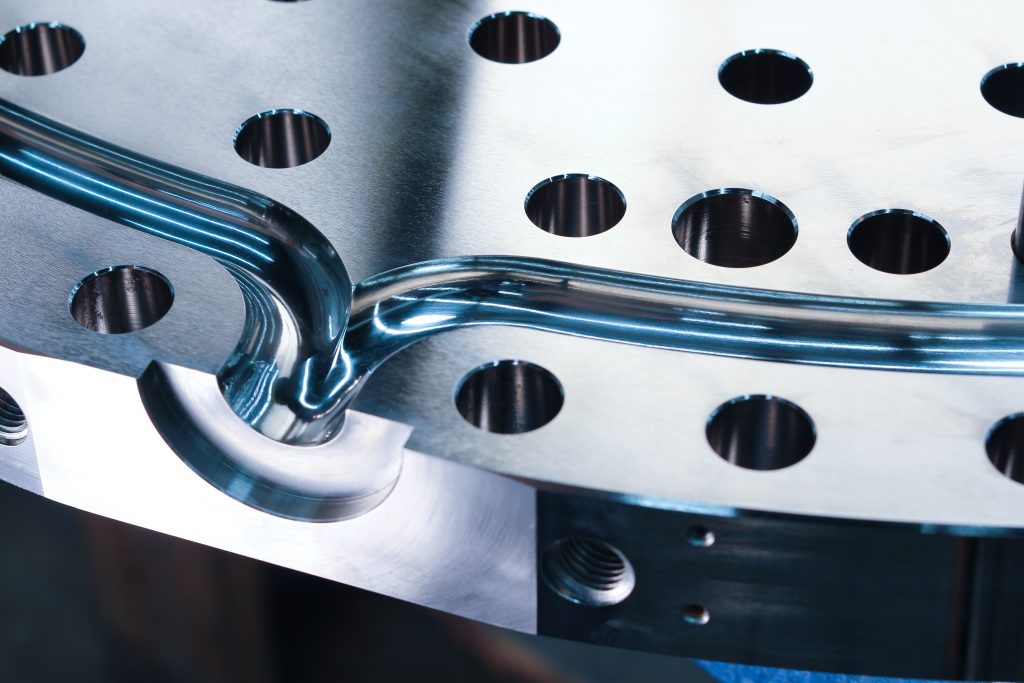

2 Different types of dies used for blown film extrusion. Adapted from... Download Scientific

To do so, the blow up ratio and the draw down ratio are utilized. The amount of air supplied to the inside of the bubble is directly related to the amount the film is "blown up", and as a result, oriented in the transverse direction and is characterized the blow up ratio (BUR). The blow up ratio is simply the ratio of the final diameter of.

.